Plastic injection molding is a manufacturing process where molten

thermoplastic material is injected under pressure into a precision-engineered

metal mold cavity. The plastic cools and solidifies, taking the exact shape of

the cavity. This highly efficient and cost-effective process allows for high

volumes of customized parts to be produced quickly and consistently. It is

widely used in a variety of industries, including automotive, electronics,

medical, and consumer productsoffering high precision, repeatability, and

customization options.

Overall, plastic injection molding is a versatile and essential manufacturing

process that enables the production of a wide range of plastic parts and

products with high precision, repeatability, and cost-effectiveness.

The advantages of injection molding production can be

summarized as follows:

Injection molding can handle highly complex parts, offering consistency and the ability to manufacture millions of nearly identical parts.

Injection molding generates very little post-production waste compared to traditional manufacturing processes. Any unused or discarded plastic can be reground and recycled for future use.

Injection molding is faster compared to other methods, with high production output rates making it more efficient. Each molding cycle typically lasts between 15 to 120 seconds, allowing for more parts to be produced within a given production timeframe.

Injection molding operations have relatively low labor costs compared to other types of molding processes. The ability to produce high-quality parts at high rates helps reduce manufacturing costs through efficiency and effectiveness.

Over the years, the strength and durability of plastics have significantly increased. Modern lightweight thermoplastics can even endure the harshest environments, sometimes even surpassing metals in certain scenarios.

Injection molding is commonly used in the automotive industry, among many others, to create lightweight plastic parts. Using plastic components helps reduce weight compared to metal parts.

Injection molding offers flexibility in terms of the plastics used and the ability for original equipment manufacturers (OEMs) to customize color selections to meet specific project requirements.

Producing high-volume but complex plastic parts requires a consistent, repeatable process to achieve tightly toleranced designs. The injection molding process helps ensure consistent quality as each part continuously use s the same mold, backed by continuous improvement practices in injection molding machines that incorporate current leading technology.

Plastic injection molding is a versatile manufacturing process utilized across various industries for producing a wide range of parts and components. It is commonly used in consumer electronics for precise and repeatable parts, automotive industry for durable and lightweight parts, medical devices for precise dimensions and smooth surfaces, household items for rapid and cost-effective production, packaging for lightweight, durable, and tamper-evident materials, and industrial components for precise dimensions and high tolerance levels. The precision, repeatability, and cost-effectiveness of this process make it an essential manufacturing technology in today's global economy.

Preparation

Material Selection:

Choose the appropriate plastic material based on the required properties, such as strength, flexibility, and heat resistance.

Mold Design:

Design the mold cavity to match the desired shape and dimensions of the part. The mold must be precision-engineered to ensure accurate replication of the part.

Preheating:

Preheat the mold to ensure that the plastic cools and solidifies evenly.

Injection Process:

Melting:

Heat the plastic material to a molten state. This is typically done in the injection molding machine's barrel.

Injection:

Inject the molten plastic into the mold cavity under pressure using a plunger or screw. The pressure ensures that the plastic fills the cavity completely.

Packing and Holding Pressure:

After the initial injection, additional pressure is applied to the molten plastic to compensate for any shrinkage and to ensure that the part is fully formed.

Cooling and Solidification:

Cooling:

Allow the plastic to cool and solidify in the mold cavity. This can be done using cooling channels in the mold through which water or other cooling media is circulated.

Ejection:

Once the plastic has cooled and solidified, open the mold and eject the part from the cavity.

Post-Processing:

Trimming:

Remove any excess plastic or water outlet from the part.

Inspection:

Inspect the part for defects such as cracks, warping, or incomplete filling.

Assembly:

If the part is part of a larger assembly, it may be combined with other components.

At Megaphis, we offer a full range of injection molding services. We have a professional design and production team. Your needs can be achieved well by our company.

You can rely on us to provide precisely made, high-quality molds with a minimum turnaround time of 20 days.

Got a deadline looming? No need to worry. We are equipped with enough injection molding machines to quickly process your order.

Megaphos is also experienced in processing a huge amount of moulds. We provide a wide range of material options and provide unique alternatives based on customer requirements.

Megaphos has been providing injection molding services to companies for many years. We combine our rich experience with the latest technology in the industry to provide you with dynamic and cost-effective injection molding solutions. In addition, we have a diverse team of designers and engineers composed of professionals in different fields. This allows us to meet the needs of many industries such as optical lens, medical, automotive, furniture, baby products and householding products with rich expertise.

One injection mold can be used to manufacture thousands of parts. Working with us also allows you to get a full range of injection molding services at an affordable price without having to hire multiple service providers. Our precision and short turnaround time further help to reduce production costs.

Fortunately, as our client, you will never have to worry about precision. Our CNC machines have a tolerance of about +/-0.005mm while our high precision CNC models have a tolerance of +/-0.002mm. This outstanding performance fully complies with the high-standard recommended values in the international industry, providing impeccable precision guarantee for your products.

All materials used in our production are sourced from vetted suppliers. Each production step is performed under the supervision of experts who follow our strict quality policy. Only parts and prototypes that meet our quality management standards are delivered to our customers.

We have the capability to produce more than 300+ sets of molds in a year. In addition, Megaphos Mould has built a network of vetted partners to work with us and complement our production scale. Therefore, for us, no order is too big to be delivered on time. We are also able to accept small batch orders because we know our customers serve different market sizes.

One injection mold can be used to manufacture thousands of parts. Working with us also allows you to get a full range of injection molding services at an affordable price without having to hire multiple service providers. Our precision and short turnaround time further help to reduce production costs.

We have a professional and dedicated business team who are on call 24/7 and ready to answer all your questions at any time. No matter when and where you encounter problems, you can get in touch with us immediately with just a phone call or a message to ensure that your business process goes smoothly.

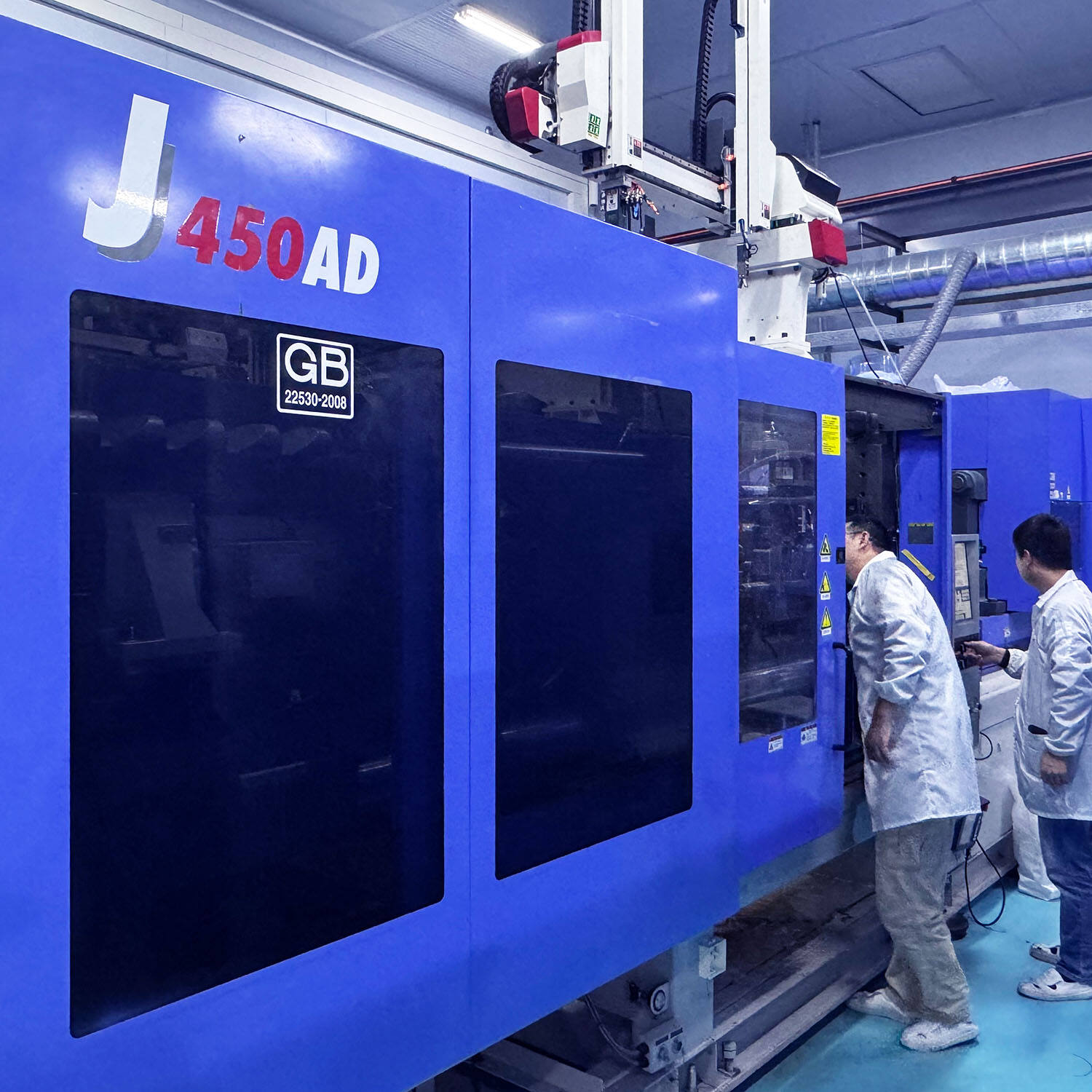

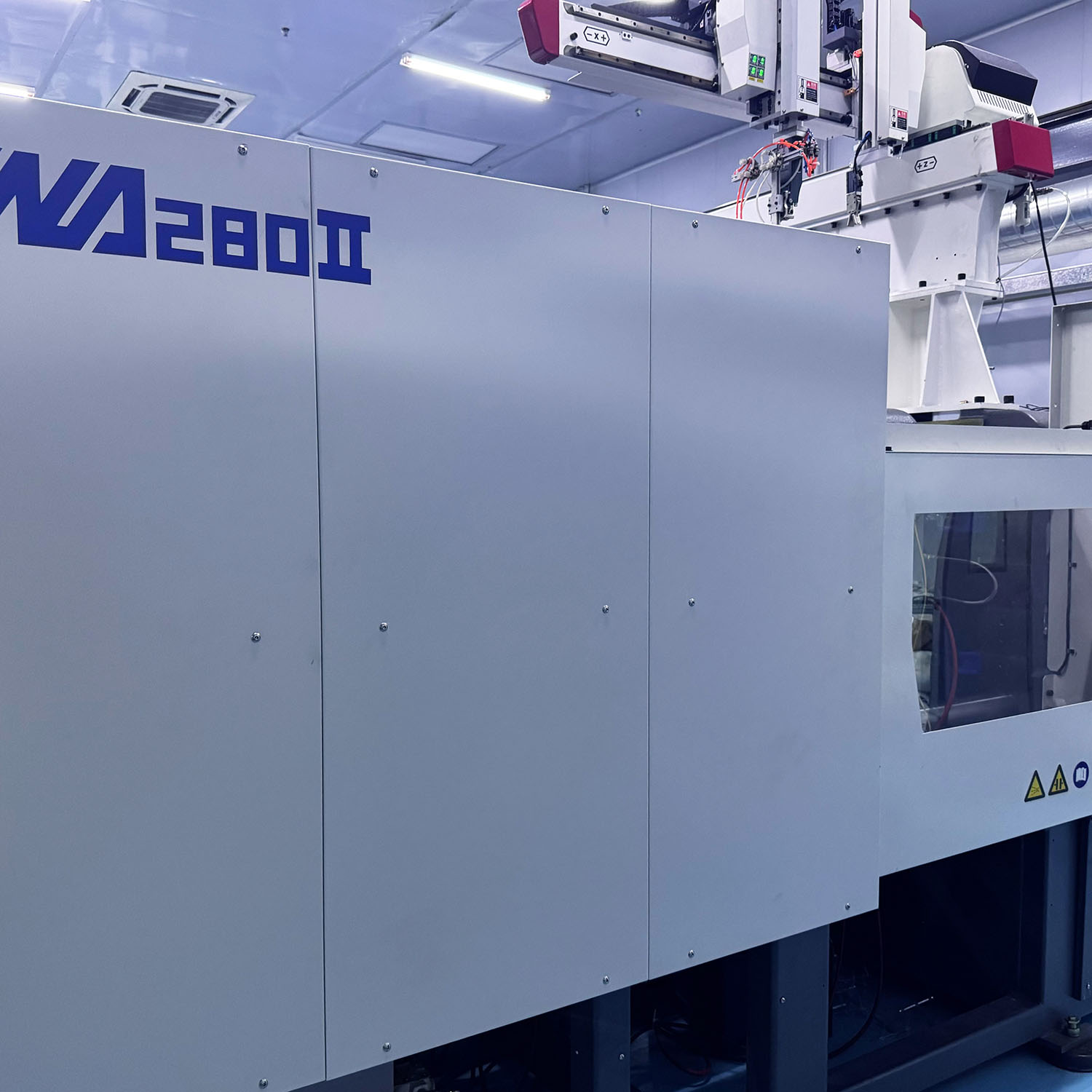

Megaphos has sufficient injection molding machines to ensure that the production progress can meet customer requirements. We have a total of 33 injection molding machines, including well-known brand equipment such as Sumitomo, JSW, LK, Fanuc, etc. We have strict requirements on the production environment to ensure the quality of the products.

In addition, we have established business relationships with certified suppliers of a wide range of raw materials. We will be happy to provide you with these materials upon request.

Workers' experience plays a vital role in injection molding production, and its importance is reflected in many aspects:

Injection molding production involves complex processes and parameter settings, such as temperature, pressure, time, etc., which have a direct impact on the quality of the final product. Experienced workers can adjust the parameters of the injection molding machine more accurately with the knowledge and skills accumulated over a long period of time, thereby ensuring the dimensional accuracy, appearance quality and performance stability of the product. In contrast, inexperienced workers may require more trial and error and debugging, which will not only increase production costs, but may also affect the delivery time of the product.

Injection molding production is a continuous process that requires workers to monitor and adjust the equipment operation status in real time. Experienced workers can quickly identify equipment failures or abnormalities and take effective measures to solve them, thereby avoiding production interruptions. In addition, they can flexibly adjust production plans according to production conditions to ensure the smooth progress of the production process. These capabilities all help to improve production efficiency and reduce production costs.

With the intensification of market competition and the continuous changes in consumer demand, injection molding manufacturers need to continuously optimize production processes to improve the competitiveness of their products. Experienced workers are able to propose suggestions and plans for improving production processes based on production experience and market feedback. For example, they can improve product production efficiency and quality stability by adjusting mold design, improving injection molding process parameters, etc. These optimization measures not only help to enhance the competitiveness of enterprises, but also create more economic benefits for enterprises.

During the injection molding production process, sometimes some complex or sudden situations may occur, such as mold damage, material changes, etc. These situations often require workers to have rich experience and expertise to respond quickly. Experienced workers can flexibly adjust production strategies according to actual conditions and take effective measures to solve problems, thereby ensuring smooth production. In contrast, inexperienced workers may not be able to respond to these situations in a timely and effective manner, resulting in production interruptions or product quality degradation.

7 Years experience,He is proficient in the installation and debugging process of the mold, and can accurately judge the mold status, effectively reducing mold damage and downtime.

Injection Molding Supervisor,9 years experience,He is extremely skilled in the operation of injection molding machines and can quickly adjust machine parameters to meet the production needs of different products to ensure stable product quality.

6 Years experience,He can quickly complete the processes of starting up, running and shutting down the injection molding machine for maintenance, significantly improving the overall output of the production line.

Injection Molding Supervisor,11 years experience.He is extremely sensitive to product quality and can promptly detect and resolve quality problems in production by observing the appearance and size of injection molded parts.