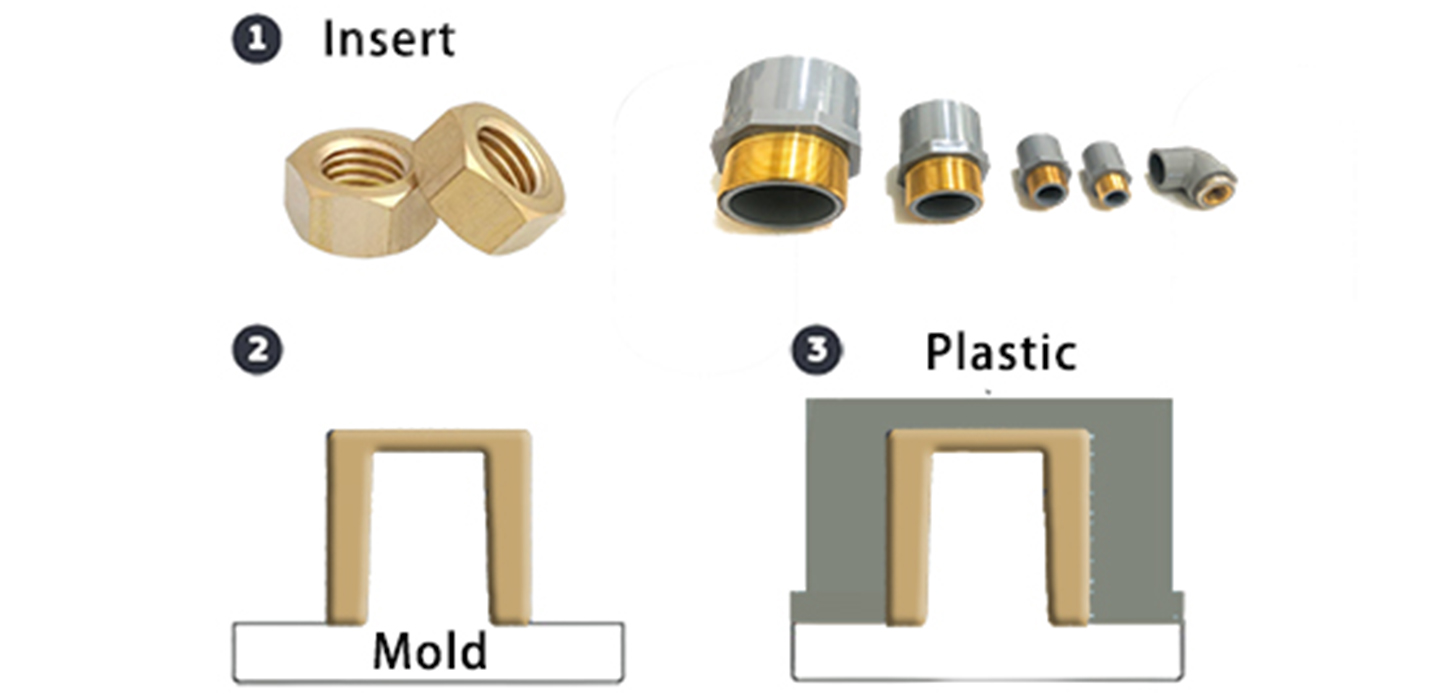

Combining different material properties: Inserts of hard materials such as

metal and ceramic can be combined with plastic. For example, when

manufacturing the sensor housing of an automobile, the insulation and easy

formability of plastics are combined with the conductivity of metal inserts,

so that the sensor housing can protect the internal electronic components

from the external environment (such as waterproof and dustproof), and can

also realize signal transmission through metal inserts.

Realize complex function integration: By placing inserts of different shapes

and functions in the mold, multiple functions can be integrated in one

injection molding process. For example, a metal insert with anti-slip texture

is added to the plastic handle mold of an electric tool, and a conductive

component that can be connected to the internal motor can also be

embedded, so that the handle has a good grip and can realize the conductive

function, meeting the complex use requirements of the product.