Megaphos is a mould design company that specializes in injection mold design and has helped many industries manufacture top-quality products.We offer injection mold design services.Just give us your specifications, and we will make the design for you.

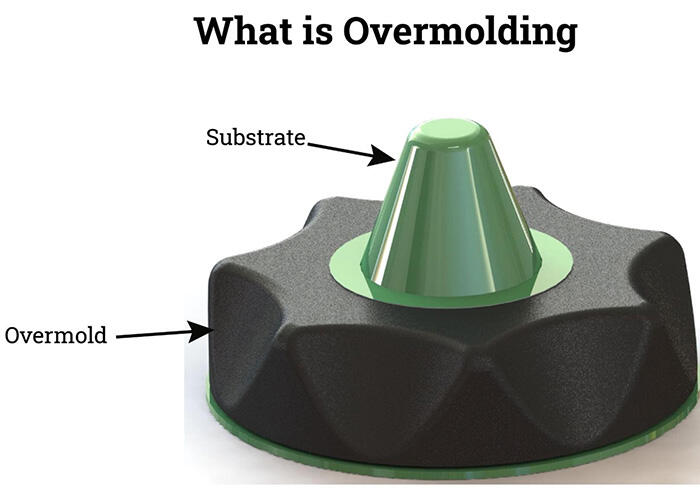

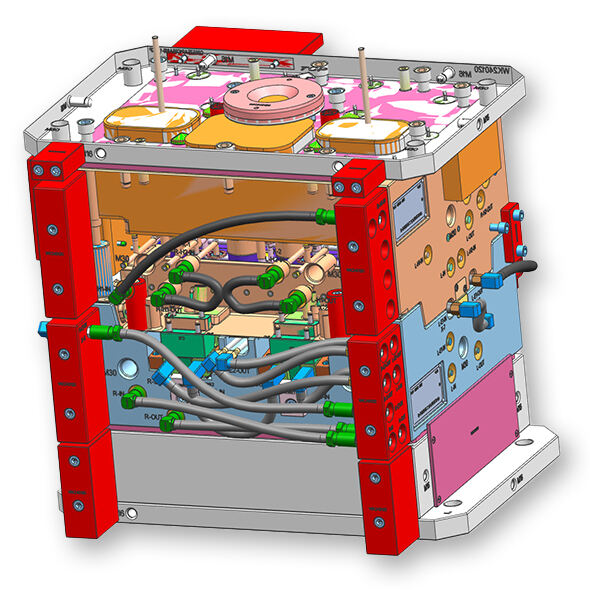

Overmolding, a manufacturing process where components are encapsulated in plastic or elastomeric material, is widely used in electronics, automotive, and medical industries for protection, durability, and insulation. It involves placing components in a mold, injecting molten material, and cooling to form a protective covering. Advantages include waterproofing, shock resistance, and a streamlined appearance. It simplifies manufacturing and reduces product cost and complexity, significantly enhancing performance and reliability.

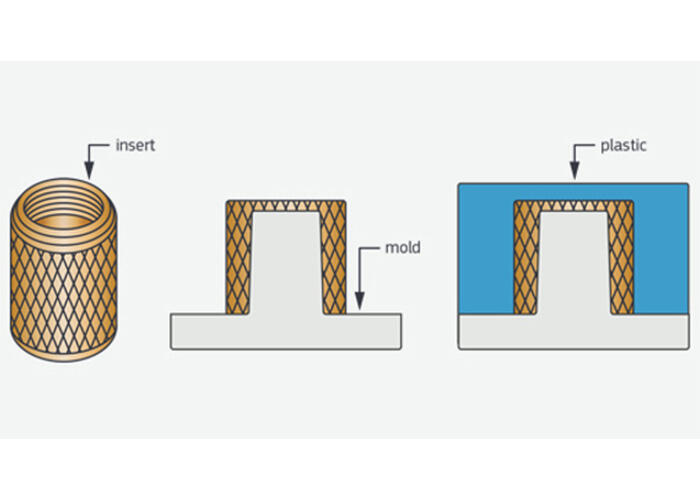

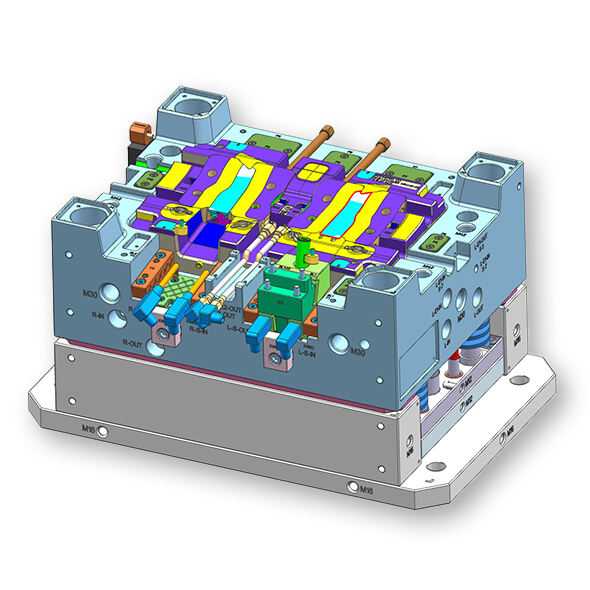

Insert molding is a specialized manufacturing technique that combines

pre-fabricated components, known as inserts, with plastic materials during

the molding process. This method allows for the integration of various

materials, such as metals or ceramics, into a single, cohesive product. By

incorporating these inserts, the process significantly strengthens the

structural integrity of the molded item and adds functionality that would be

difficult to achieve through traditional molding alone. It also offers greater

design flexibility, enabling the creation of complex, multi-material

assemblies.

In addition to these benefits, insert molding streamlines production by

reducing the need for separate assembly steps, which can lower labor

costs and increase overall efficiency. This process is highly versatile and

is widely employed in industries like electronics, automotive, and medical

devices, where product performance, strength, and cost-efficiency are

paramount.

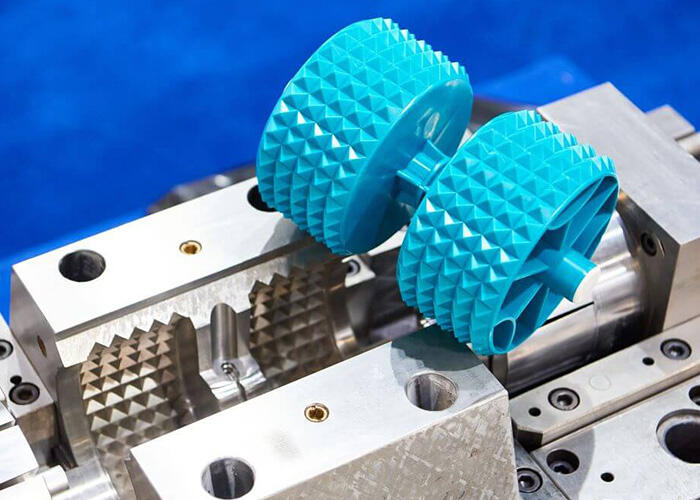

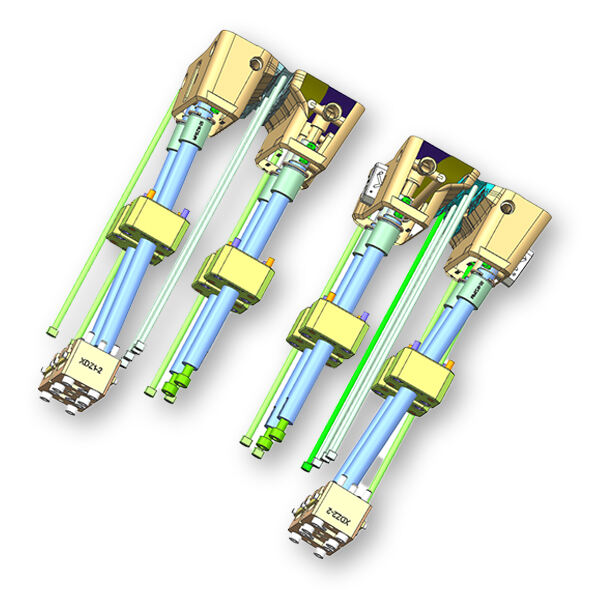

Plastic injection molding is a manufacturing process where heated plastic is injected into a mold to form a solid part. The mold is carefully designed to create the desired shape, and the plastic is injected under pressure to fill all details. After cooling and solidifying, the part is ejected from the mold and can be further processed as needed. This process is efficient and versatile, suitable for producing a wide range of plastic parts for various industries.

Before we start making your mold prototype, we need a comprehensive product 3D drawing. We will use it as the core design of your plastic mold design.

Once we receive your product specifications, we will need your confirmation. We consider creating a mold prototype to be an important part.

We will conduct DFM and mold flow analysis reports to ensure that the product meets your project requirements. You need to confirm the analysis results before we continue the production process.

Our business team offers 24/7 online support, ensuring prompt assistance and satisfaction for all your business needs.No matter the time of day or night, you can rely on us to promptly address your inquiries, resolve any issues, and ensure your satisfaction.

If you're interested in obtaining a quote for our services, you can rest assured that you won't have to wait long. We understand the importance of timely information and are committed to providing you with a comprehensive and competitive quote within just a single day. Our efficient and dedicated team works hard to ensure that you receive the information you need to make informed decisions, without any unnecessary delays.

If you have any complaints about the moulding quality, Megaphos is more than eager to offer you a complimentary design review. We firmly believe that our clients deserve the utmost excellence and are committed to ensuring your satisfaction through our dedicated service.

Before we release any molding designs, we ensure that our mold designers conduct a thorough and professional mold analysis. This rigorous process guarantees that your molds are in optimal condition, meeting the highest standards of quality and performance.

9 Years experience.Proficient in using CAD/CAM/CAE and other design software,know the characteristics of various mold materials.

11 Years experience.Possess innovative thinking and problem-solving skills, and be good at using new technologies and processes to optimize mold structure.

9 Years experience.Have many years of practical experience in cross-domain mold design projects, covering many industries such as automotive parts, electronic and electrical, and medical device molds.

8 Years experience.Able to effectively manage mold design projects, from demand analysis, solution design, manufacturing tracking to post-commissioning

7 Years experience.Have good communication and coordination skills, and be able to work closely with cross-departmental teams to jointly solve problems in projects.

In the manufacturing industry, mold design is a critical link in the production process, especially in industries such as automotive lighting optics, electronics, and consumer products. A factory's mold design capabilities directly affect product quality, production efficiency, and overall competitiveness. This article delves into the various aspects of mold design capabilities that a factory can demonstrate, emphasizing the importance of technology, expertise, process optimization, and innovation.

Injection Mold Gate Design The design of the gate in injection molds is important as it controls melt flow, impacts product quality (both appearance and internal aspects), and affects production efficiency (injection cycle and scrap generation).

The design of the cooling system for injection molds is of great importance. In terms of product quality, it can control dimensional accuracy, reduce deformation and internal stress, and improve the appearance. In terms of production efficiency, it can shorten the molding cycle and extend the service life of the molds, which is of great significance for injection molding

The injection molding system design is crucial as it impacts product quality (ensuring accuracy, improving appearance and internal quality), production efficiency (accelerating speed and enhancing stability), and cost control (increasing material utilization and reducing energy consumption).

The design of the ejection system for injection molds is of great importance. In terms of demolding, it can ensure smooth demolding and improve the demolding efficiency. Regarding product quality, it can guarantee product precision and protect the appearance. As for the molds, it can extend their service life and facilitate maintenance.

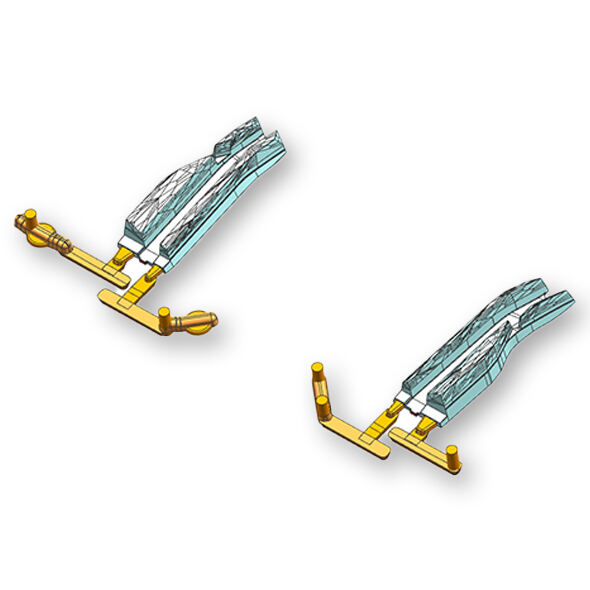

At the core of modern mold design lies the integration of Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE) technologies. These tools facilitate the creation of precise, functional, and efficient molds.

CAD software enables designers to create three-dimensional models of molds with high precision. This precision is critical for ensuring that the final product meets exact specifications. With features like parametric modeling and assembly simulations, designers can predict and rectify potential issues early in the design phase, reducing the need for costly revisions later.

CAM software translates CAD designs into machinable data, guiding computer -controlled machinery like CNC milling machines and lathes. This integration ensures that the manufacturing process aligns seamlessly with the design intent, minimizing errors and enhancing productivity. Moreover, CAM software optimizes toolpaths, reducing machining time and material waste.

CAE tools play a crucial role in mold design by allowing for virtual testing and analysis. Finite Element Analysis (FEA) can predict stress distributions within the mold under various loading conditions, ensuring structural integrity. Thermal analysis helps in understanding the mold's heat transfer characteristics, guiding the design of cooling systems to maintain optimal molding temperatures.

Beyond technological advancements, the expertise and experience of a factory's mold design team are indispensable.

A highly skilled workforce is the backbone of any successful mold design operation. Designers with extensive experience in mold-making understand the intricacies of material science, mold construction, and manufacturing processes. This expertise allows them to anticipate potential problems and devise innovative solutions.

Selecting the right mold material is crucial for achieving the desired product quality and mold life. Designers must have a deep understanding of various mold materials, including tool steels, aluminum alloys, and composites. They must know how these materials respond to different processing conditions, such as temperature and pressure, and their resistance to wear and corrosion.

The mold design industry is constantly evolving, driven by advancements in technology and changing customer demands. Factories with strong mold design capabilities invest in continuous learning and improvement programs for their employees. This includes training on the latest CAD/CAM/CAE software, attending industry conferences, and collaborating with research institutions to stay abreast of the latest trends and innovations.

Efficient mold design is not just about creating accurate models, it's also about optimizing the entire design-to-manufacture process.

DFM principles ensure that the mold design considers the practical aspects of manufacturing. This includes factors like mold accessibility for machining and assembly, ease of mold maintenance, and the use of standard components to reduce costs. By incorporating DFM practices, factories can enhance production efficiency and reduce lead times.

Effective mold design often involves collaboration between designers, engineers, and manufacturing personnel. This cross-functional teamwork ensures that all aspects of the mold design are thoroughly reviewed and optimized. Collaborative design tools facilitate real-time communication and data sharing, enabling faster decision-making and reducing the risk of miscommunication.

Managing mold design projects efficiently is key to meeting tight deadlines and ensuring quality. Factories with advanced mold design capabilities typically employ project management software to track progress, allocate resources, and monitor key performance indicators. This ensures that projects stay on track, and any deviations are quickly identified and addressed.

In today's highly competitive and cutthroat market, where businesses are constantly vying for a larger market share and striving to outperform their rivals, the capacity to innovate mold designs by introducing novel concepts, materials, and manufacturing techniques, as well as the ability to customize them precisely according to the unique requirements and specifications of different clients, has emerged as a truly significant differentiator. This not only enables companies to stand out in the crowded marketplace but also paves the way for long - term success and sustainable growth. designs is a significant differentiator.