Our EDM machining processes stand out as premium in the market, underpinned by unparalleled professionalism that has consistently positioned us as a leading force in the industry. We are relentless in our pursuit of evolution, seamlessly integrating our extensive experience with cutting-edge manufacturing technologies. Here are some key benefits of our EDM machining services:

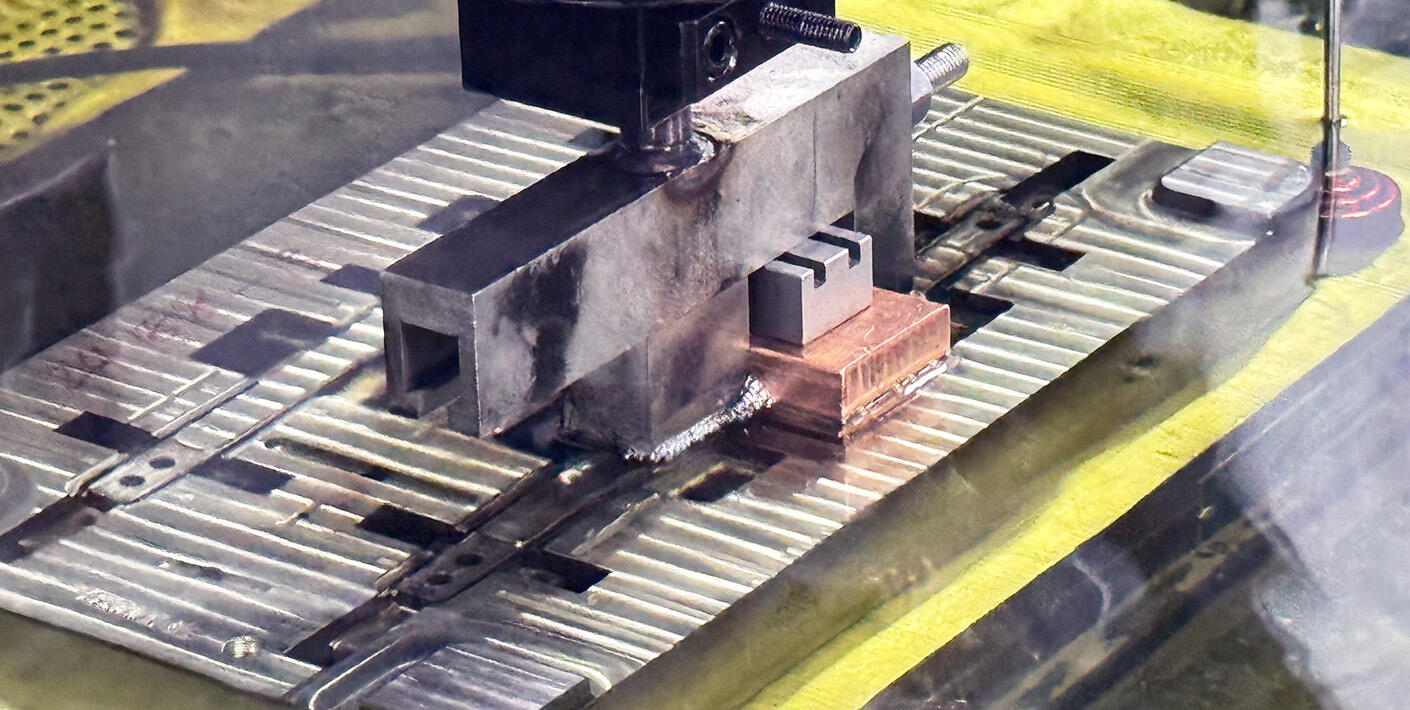

We have introduced the world's leading Sodick EDM machine tools, which not only have high-precision and high-efficiency processing capabilities, but also integrate the latest intelligent control technology to achieve high-precision processing of complex three-dimensional shapes. By using fine electrodes and advanced discharge control technology, we can significantly improve processing speed and surface quality while ensuring processing accuracy.

We have an experienced and skilled operation and R&D team. Team members are not only proficient in the operation and maintenance of EDM machines, but also continue to explore and optimize processing parameters to ensure that each mold material can get the most suitable processing solution. In addition, we also provide customized mold solutions to meet the special needs of customers.

Our EDM machines cover the full range of processing sizes from small precision parts to large mold components. Whether it is hard-to-process materials such as carbide, stainless steel, titanium alloy, or mold cavities with complex structures, we can provide high-quality processing services. This has greatly broadened our business scope and enabled us to serve a wider customer base.

We have established a complete quality management system, from raw material inspection to processing process monitoring to finished product inspection, every step is strictly controlled. After EDM processing, the mold parts will undergo precision measurement and surface quality inspection to ensure that each product meets or exceeds customer expectations.

We are well aware of the importance of time for mold manufacturing, so we have established a quick response mechanism. Whether it is technical consultation, sample production or mass production, we can give customers satisfactory replies and solutions in the shortest time to ensure that the project is delivered on time.

We continue to explore new boundaries of EDM technology, cooperate with universities and scientific research institutions, and carry out R&D and application of cutting-edge technologies. Through technological innovation, we continue to improve processing efficiency, reduce costs, and provide customers with more competitive products and services.

EDM machining, or Electrical Discharge Machining, plays a vital role in mold making and has an irreplaceable role and importance. The following is a detailed explanation of the specific role and importance of EDM machining in mold making:

EDM machining is a special processing method that uses the electro-erosion effect generated by the pulse discharge between two electrodes immersed in the working fluid to erode conductive materials. When the pulse voltage reaches a certain value, spark discharge will be generated between the two electrodes, forming an instantaneous high temperature and high pressure discharge channel, so that the material on the surface of the workpiece is eroded, thereby achieving the purpose of processing.

Processing complex shapes:EDM machining can process materials and complex-shaped workpieces that are difficult to cut by traditional cutting methods, such as precision small cavities, narrow slits, grooves, corners, etc. In mold manufacturing, especially in small injection mold manufacturing, due to the large number of grooves and corners and high precision requirements of its cores, sliders, inserts, inclined pins and other parts, EDM machining can solve these problems well.

Improve machining accuracy: EDM machining can achieve micron-level machining accuracy and meet the strict requirements for accuracy in mold manufacturing. Through the automatic electrode exchange of the machine tool and the use of special electrode fixtures, EDM machining can ensure the correct position relationship between the electrode and the machine tool, reduce the time of clamping and repeated adjustment, and improve machining accuracy.

Save materials and time: Compared with traditional cutting, EDM machining does not need to remove a large amount of material, but only needs to remove a small amount of material through electrolytic erosion, so it can save materials. At the same time, since EDM machining does not require complex cutting tools, it can shorten the machining time and improve production efficiency.

Suitable for difficult-to-machine materials: EDM machining is suitable for machining various high-strength, high-hardness, high-toughness, high-brittleness and high-purity conductive materials, such as cemented carbide, hardened steel, etc. These materials are often encountered in mold manufacturing, and EDM machining can easily cope with the challenges of these difficult-to-machine materials.

Making Improve mold quality: The high precision and consistency of EDM machining ensure the matching accuracy and interchangeability between mold parts, thereby improving the overall quality of the mold. High-quality molds can produce high-quality products and meet the strict requirements of customers.

Shorten the mold manufacturing cycle:The efficient processing capability of EDM machining shortens the mold manufacturing cycle and enables the mold to be put into production and use faster. This helps enterprises respond to market demand quickly and improve market competitiveness.

Reduce mold manufacturing costs:Since EDM machining does not require complex cutting tools and a large amount of material removal, it can reduce the manufacturing cost of the mold.

At the same time, the efficient processing capability of EDM machining also reduces the time of manual intervention, further reducing production costs. Promote mold manufacturing technology innovation:EDM machining, as an advanced special processing technology, has promoted the continuous innovation and development of mold manufacturing technology. With the continuous advancement of science and technology and the continuous changes in market demand, EDM machining will play a more important role in mold manufacturing.

EDM (Electro-Discharge Machining) plays an important role in the manufacture of injection molds and has a significant impact on the quality of molds. The following is a detailed analysis of how EDM processing affects the quality of injection mold manufacturing from several aspects:

During EDM processing, pulse discharge occurs between the electrode and the workpiece, generating high temperature to melt and vaporize the workpiece material, thereby forming a thermal erosion layer on the mold surface. This thermal erosion layer includes a recast layer (white layer) and a heat-affected zone. The white layer is formed by the rapid cooling and re-solidification of the molten metal that cannot be removed in the insulating liquid. Its structure is significantly different from that of the base material and contains a large amount of carbon. The heat-affected zone retains the metallographic structure of the parent material due to heat treatment, but may be affected to a certain extent.

Impact of the white layer: Microcracks may occur in the white layer. If the white layer is too thick or is not removed by EDM finishing or polishing, these microcracks may cause premature damage to the component and reduce the corrosion resistance and fatigue resistance of the material.

Effect of heat-affected zone: Although the heat-affected zone retains the metallographic structure of the masterbatch, its properties may change due to the influence of heat treatment, such as hardness and toughness.

The surface finish of the mold after EDM processing depends on multiple factors, including current intensity, time effect, electrode material, etc. Current intensity and time effect: The increase of current intensity and time effect will lead to increased surface roughness. Therefore, low current intensity and small discharge pulse time are required to obtain higher surface finish in the finishing stage.

Electrode material: The electrode material has little effect on the surface integrity of each layer in the cavity, but it plays an important role in the surface finish of the cavity. Electrode materials with good microstructure (such as small and regular particle shape) can produce a more uniform cavity surface.

EDM processing has high processing accuracy, especially when processing molds with complex shapes and small sizes. High-precision processing: By using fine electrodes and advanced discharge control technology, EDM can achieve micron-level processing accuracy. Shape complexity: EDM can process various complex shapes and micro-sized mold parts to meet the requirements of injection molds for shape complexity.

The efficiency and cost of EDM processing in injection mold manufacturing are also worthy of attention.

Processing speed: EDM processing speed is affected by many factors, including discharge pulse time, current intensity, electrode loss, etc. By optimizing these parameters, the processing speed can be increased and the cost can be reduced.

Electrode loss: Electrodes will be lost during EDM processing, especially in the rough processing stage. Therefore, it is necessary to select suitable electrode materials and processing parameters to reduce electrode loss and reduce production costs.

Although EDM processing has many advantages in injection mold manufacturing, it also has certain application limitations. Material limitations: EDM processing is mainly suitable for conductive materials. For non-conductive materials or materials with poor conductivity, special treatment methods or alternative processing technologies are required.

Surface metamorphic layer: After EDM processing, a metamorphic layer (including white layer and heat-affected zone) will be generated on the mold surface, which may affect the performance and service life of the mold. Therefore, these metamorphic layers need to be further removed in some applications.

In summary, EDM processing has an important impact on the quality of injection mold manufacturing. In the mold manufacturing process, it is necessary to select the appropriate EDM processing method according to the specific requirements and material properties of the mold, and take corresponding measures to optimize the processing parameters and process to improve the production efficiency and quality of the mold.